Data-Driven Operational Excellence

Increase in Profits through Production Enhancement and Asset Management

Authors: Herman Aguirre-Jofré, Ariana Carrazana Di Lucia

For the second consecutive year, MiningiDEAS is supporting the financial management of a cement-producing mining company.

The initial objectives of the consultancy were as simple as organizing the production databases and leading a daily operations meeting.

The mine we are discussing in this case study does not have any kind of technological system, and all the information is digitized in Excel spreadsheets by on-site managers. Before the arrival of MiningiDEAS, these sheets used to be sent to supervisors and managers, without any form of analysis or formatting that summarized what had happened.

The manually recorded information each morning includes:

- Number of cycles of each truck from the production benches to the crusher.

- Number of cycles of each truck from the post-crusher stock to the cement processing plant.

- Meters drilled by each of the drill rigs.

- Daily, monthly, and yearly accumulated availability of each piece of equipment.

- Grade of the materials processed by the crusher. (The mine lacks an appropriate block model.)

- Routine inspections of the facilities.

- Alerts and comments about equipment and on-site conditions.

Initial Steps

During the first advisory season, MiningiDEAS faced an important technical dilemma: is it possible to increase production and productivity for a company that lacks any technological systems emitting data? The answer is yes.

In every mine, no matter how small, there are computers and on-site managers who record their daily productions, progress, and comments in Excel sheets. The problem is that this information, generally tabulated in unstructured forms, does not generate any management mechanism.

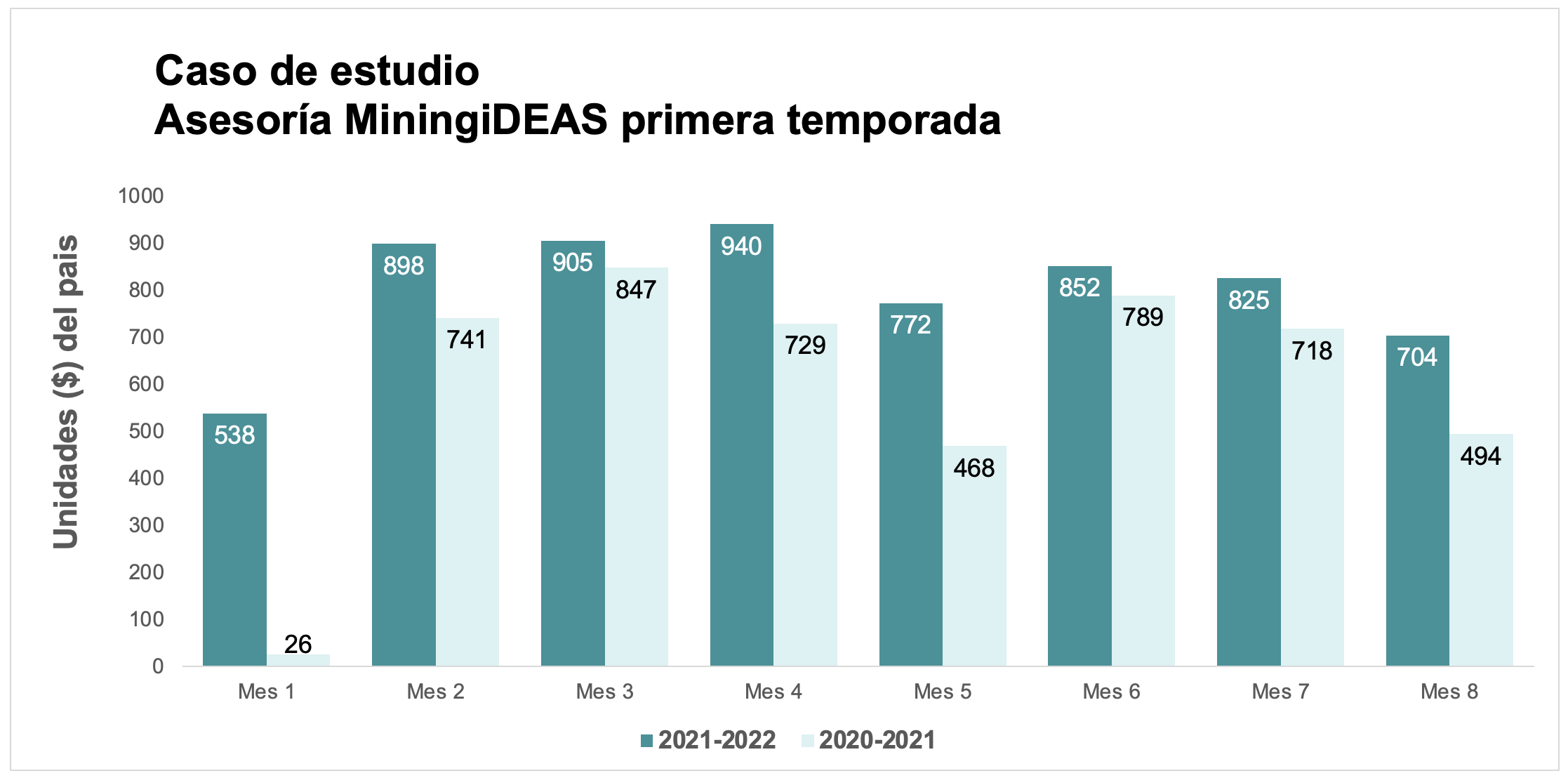

Based on these documents, MiningiDEAS' first task was to identify critical variables, build an appropriate structured database, and present the indicators in a way that allowed for the creation of a management system with goals and commitments. After just one month of work, which took place before the season started, the production trend was as follows:

Production profile for the 2020-2021 season advised by MiningiDEAS compared to the previous season.

The credit can never be 100% attributed to a consultancy alone. The results shown in the previous graph are the outcome of organized efforts and a team of operators with a clear focus on a goal. Defining this goal and the set of KPIs that organization members should observe was the significant contribution of MiningiDEAS.

The Path of Consistency

After achieving excellent results in the 2021-2022 season, MiningiDEAS was once again contracted to further optimize production.

It's important to remember here that no work sustains itself over time. Achieving operational excellence requires consistency and the introduction of habits that need to be continuously nurtured. If results are achieved with a consultancy, it's inappropriate to eliminate it for cost reduction. Our client understood this and once again placed their trust in us.

This mining company has not yet incorporated technology into its processes, but they have plans to invest in systems that will allow them to see and increase their awareness level regarding their production processes. Despite continuing with manual methods, there will always be areas for improvement in a mine.

In this second year, it can be mentioned that the organization is mature in aspects such as tracking key indicators, achieving goals, fulfilling commitments, and attending performance dialogues led by MiningiDEAS. Therefore, it's possible to implement new methodologies in asset management and waste elimination.

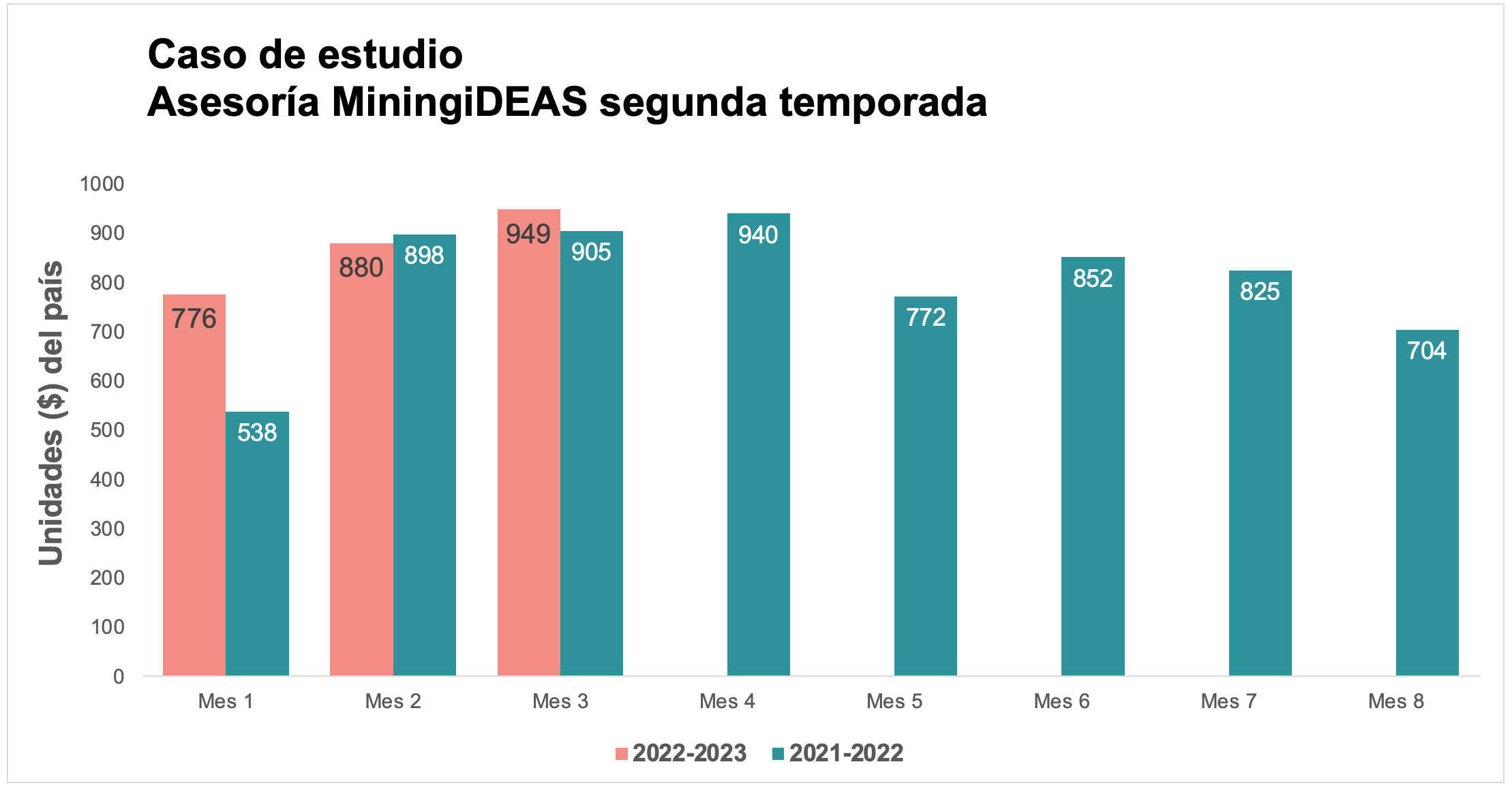

The results are evident. For this new year, the production trend is as follows:

Production profile of the 2020-2021 season advised by MiningiDEAS compared to the previous season.

Enlaces de interés

If you wish to receive consultations from MiningiDEAS to enhance your production and increase your company's profits, please get in touch with our team of specialists.