3D Modeling of a Coal Mine Slurry Pool

Authors: Leopoldo Serpa and Ariana Carrazana

The output/code/data analysis for this paper/report was generated using Leapfrog Software. Copyright © Seequent Limited. Leapfrog and all other Seequent Limited product or service names are registered trade marks or trade marks of Seequent Limited. Powered by Leapfrog.

The evaluation of secondary resources in tailings dams opens up new possibilities for the use and optimization of mining liabilities. This article briefly describes how 3D modeling provided valuable information in a case study of a mining company dedicated to the extraction, beneficiation, commercialization, and production of electrical energy from coal. For more information, refer to Serpa's academic work (2019).

The sub-bituminous coal extracted from the deposit is beneficiated (separated by dense media) to meet the demands for its various uses. As a result of the beneficiation process, tailings are generated and deposited in so-called slurry pools. One of the currently inactive pools was studied with the aim of preliminarily identifying and quantifying the areas with the highest potential for reuse (re-exploitation) for thermal purposes.

For the modeling of sedimented materials, visual descriptions of 35 wells distributed over a 20mx20m grid were used, with depths ranging from 2.00m to 3.10m.

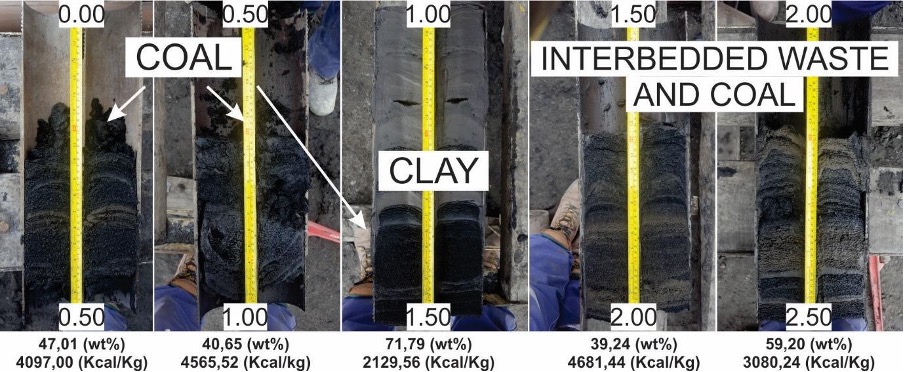

In the visual description (Figure 1), three types of materials were identified and named coal, clay, and waste. These are arranged in layers with thicknesses ranging from millimeters to tens of centimeters, interspersed with each other in different proportions.

Figura 1: foto donde se muestra la disposición laminar y los tipos de materiales presentes. Coal = carbón, clay = arcilla, waste = estéril.

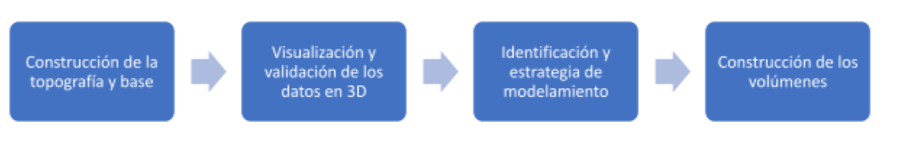

The distinction between clay (very fine material with plastic behavior) and waste (silt and sands) is based on the difficulties each material presents for the beneficiation process due to its grain size (especially clay). This distinction is relevant because for thermal purposes, both are considered gangue/waste, but their behavior is very different for eventual reprocessing. The workflow used to model the sedimented materials is shown in Figure 2.

Figura 2: flujo de trabajo involucrado en el proceso de modelamiento 3D.

The importance of each stage is briefly detailed below:

- 1. Construction of topography and base: These determine the volume of the pool, representing its roof and base. Data from wells and topographic surveys were used.

- 2. Visualization and validation of 3D data: This allows for a 3D view of how materials are distributed within the pool, searching for errors and/or inconsistencies in the data and interpretations.

- 3. Modeling strategy: This stage is very important as it decides how to approach the modeling, after identifying or interpreting patterns in the data. These will allow reaching a model that is consistent with the process to be modeled (discharge) and with an appropriate complexity.

- Volume construction: Finally, solids representing sectors with different materials are constructed volumetrically.

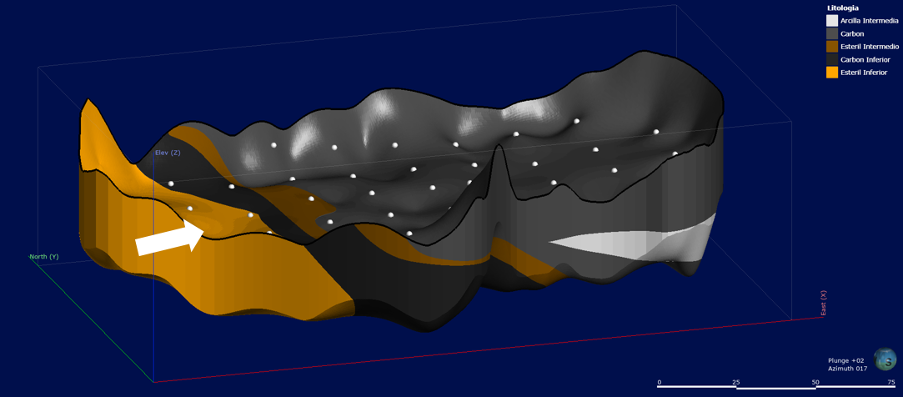

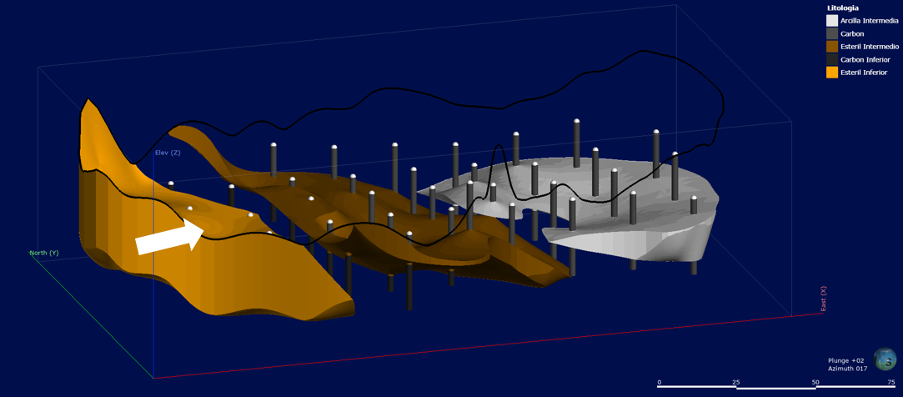

For the present case study, Leapfrog Geo software (academic license) owned by Bentley was used. The modeling strategy used (Figures 3 and 4) allowed for the interpretation and modeling of levels: lower coal, upper coal, lower waste, upper waste, and clay. The distinction between upper and lower was defined by their vertical position in the pool. The vertical and lateral distribution of levels is associated and conditioned by dynamic deposition processes, mainly hydraulic and density separation, and by differences in discharge flows (or pulses).

Figure 3: 3D visual of the pool with the distribution of the modeled levels (Coal = upper coal, intermediate clay = clay) indicating the approximate position of the discharge point (white arrow).

Figure 4: 3D visual of the pool with the distribution of the levels that constitute gangue, that is, lower and upper sterile and clay (intermediate clay = clay). The approximate position of the discharge point is also indicated (white arrow).

Conclusions

- The 3D model allowed correlating the distribution of coal and gangue (clays and silt-sands) with theoretical models of particle distribution in tailings dams (Kossoff et al., 2014; Papageorgiou, 2004; Vick, 1990).

- Coal tends to concentrate mainly towards the central zone, although it is widely distributed in the pool, interspersed with clay and waste.

- Waste (silt-sands) is primarily concentrated near the discharge point, where its thicknesses are more significant.

- The clay level is located from the central zone of the pool, and its thickness progressively increases towards the west wall.

Bibliography

Kossoff, D., Dubbin, W. E., Alfredsson, M., Edwards, S. J., Macklin, M. G., & Hudson-Edwards, K. A. (2014). Mine tailings dams: characteristics, failure, environmental impacts, and remediation. Applied Geochemistry, 51, 229-245.

Papageorgiou, G. (2004). Liquefaction assessment and flume modelling of the Merriespruit gold and Bafokeng platinum tailings (Doctoral dissertation).

Serpa, L. D., (2019). Characterization and 3D Modeling of a Slurry Pool for Possible Thermal Exploitation. Evaluation of Ash Content and Higher Heating Value. Río Turbio Coalfield, Güer Aike, Santa Cruz (Unpublished Thesis). University of Buenos Aires, Buenos Aires, Argentina. 94p.

Vick, S. (1990). Planning, Design, and Analysis of Tailings Dams. BiTech Publishers Ltd., 1990.