Financial and Operational Management

Improvements in Contract Administration for Cement Producers

2018-2019

Author: Herman Aguirre-Jofré

In this project, MiningiDEAS supported the financial and operational management of the company.

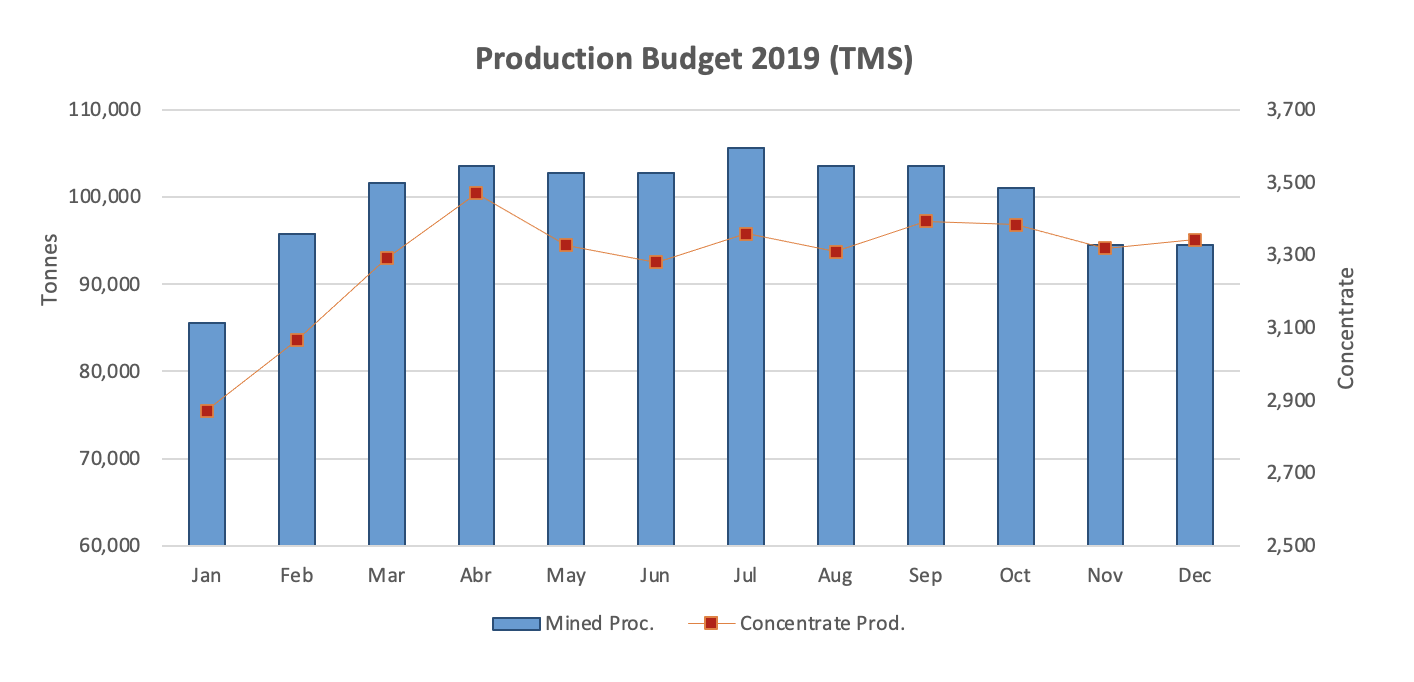

In financial matters, we applied our knowledge in reducing operational costs (OPEX) in mining, plant, and marketing. We reviewed capital costs for ongoing operations and new projects (CAPEX) and assisted in constructing the budget for the year 2019.

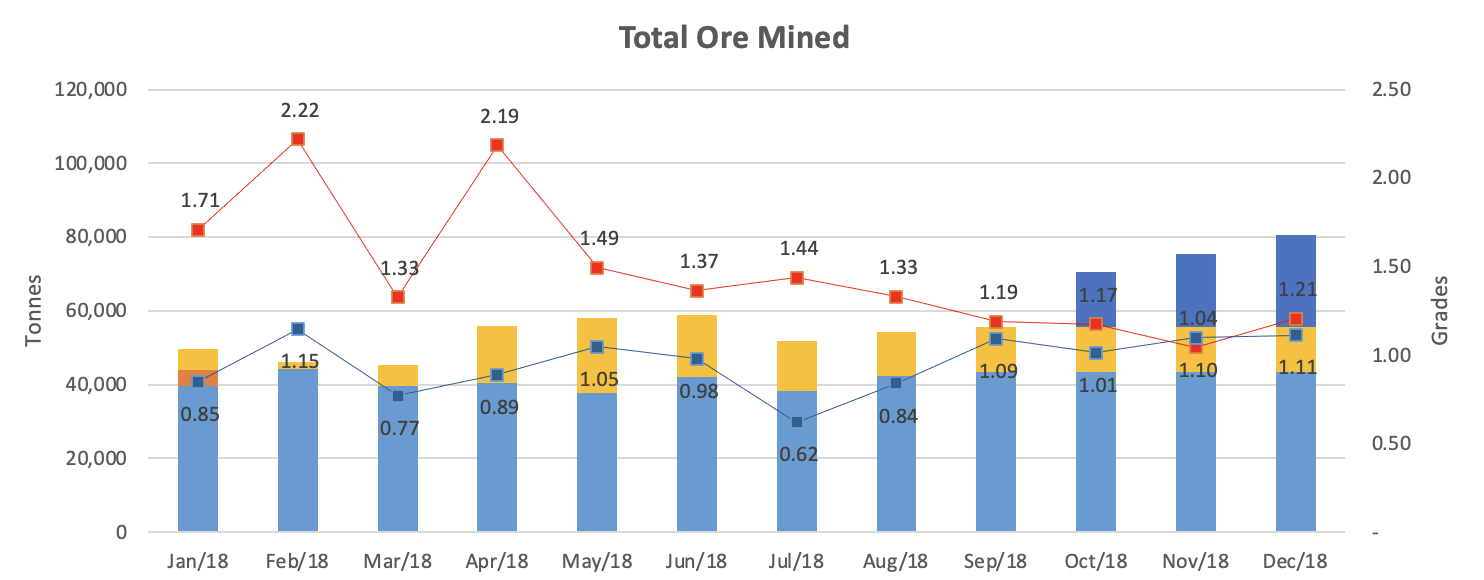

The first major task was to stabilize the production for the current year (2018), and then gradually increase the tonnages sent to the processing plant. Special attention was paid to the head grades feeding the plant to reduce variability and improve recovery, without dramatically altering the configurations previously used.

Once the feeds became consistent, our MiningiDEAS team assisted in constructing the mining plan. Mining plans include tons of material to be removed, minerals to be sent to the plant, grades, and resources needed to accomplish it. Based on our extensive mining knowledge, we defined appropriate planning and economic criteria for this type of deposit (epithermal copper and gold veins).

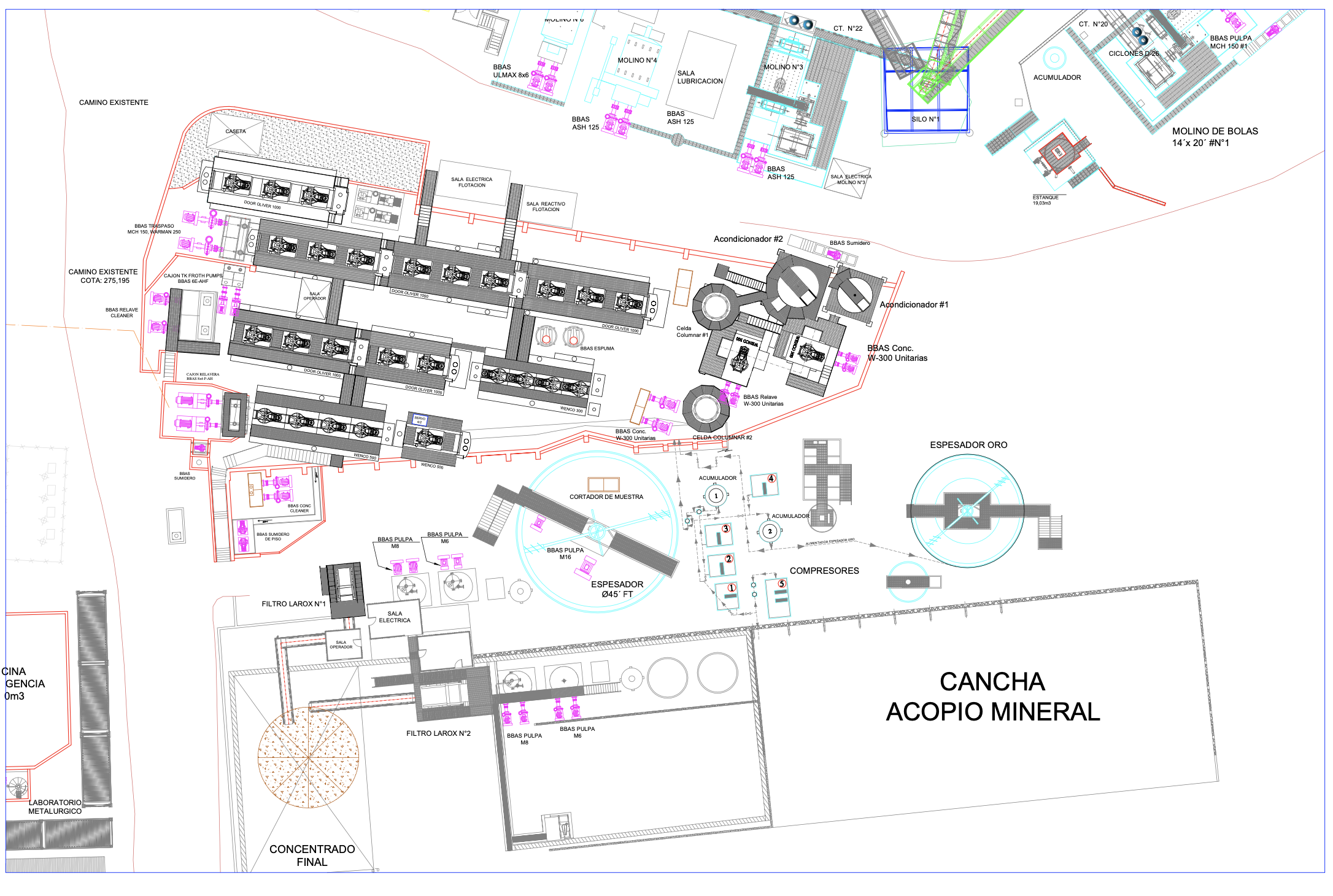

The key to improving the production process was to take complete control of the processing plant. The mineral blends being processed and the configurations used for their recovery were carefully studied. One of the complexities of this mine was that it not only processed its own minerals but also processed minerals from nearby mining companies that did not have processing plants (a process also known as tolling). This type of commercial practice is common among medium-sized mining companies in northern Chile. However, the impacts on recoveries are significant because the types of minerals vary considerably from one mine to another.

Processing plant plan.

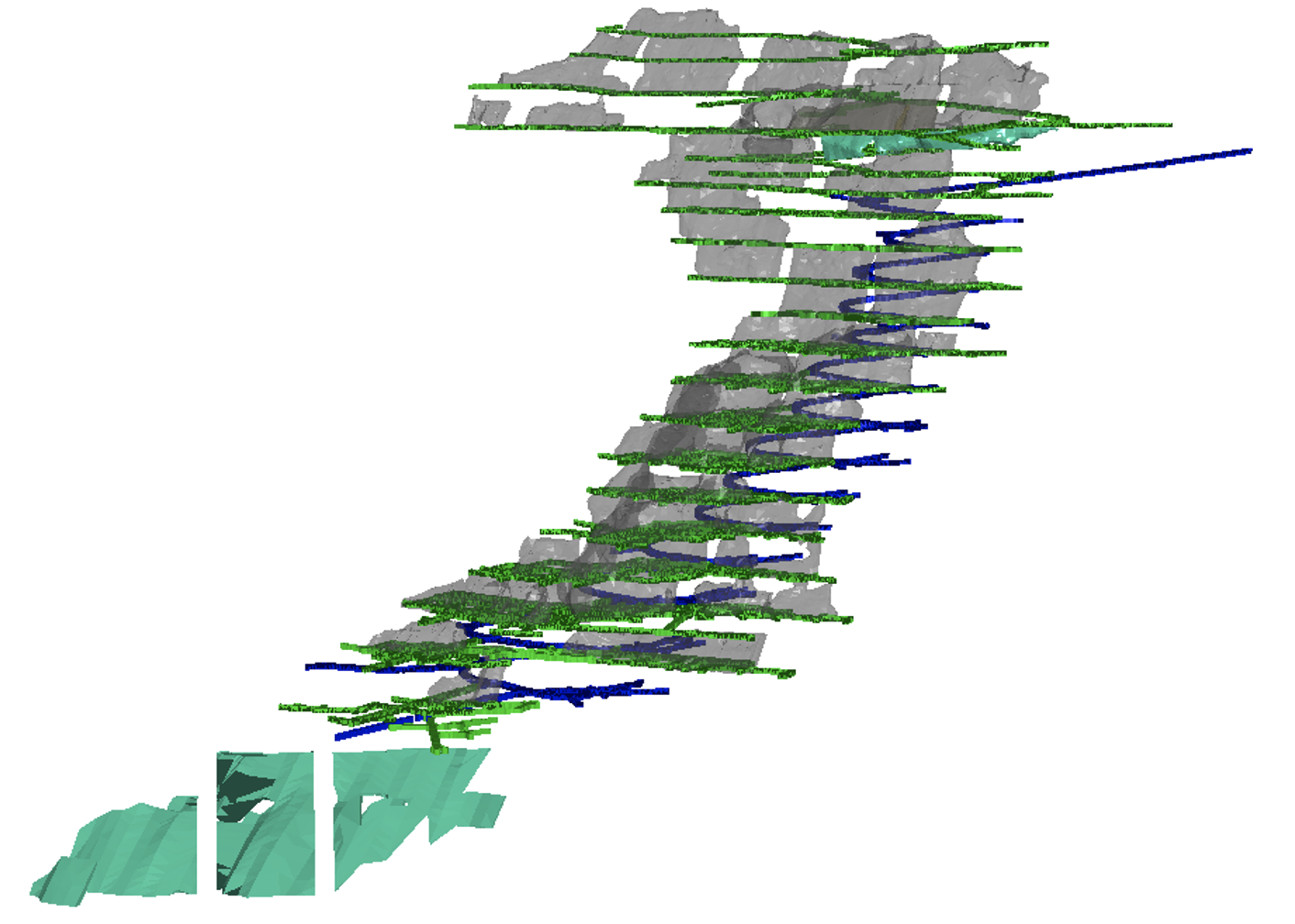

To complete the advisory process, our support and recommendations on implementing best operational practices for underground mining methods were essential. We thoroughly reviewed truck and LHD extraction patterns in self-supported chambers (sublevel stoping). We reviewed maintenance plans for the equipment fleet, calculated productive cycle times, estimated delays in the haulage circuit, and defined performance dialogues to inform supervisors of KPIs and goals to achieve.

Isometric view of the underground mine exploited by the open stoping sublevel method..