Increase in Production at a Large-Scale Mining Company

Application of Lean Management Methodologies

June 2020 - March 2022

Author: Herman Aguirre-Jofré

MiningiDEAS provided consultancy services to the Mining Management of a significant mine in Chile for almost 2 years. This mine, an open-pit operated by an oriental company, produces both sulfide and oxide copper and has a flotation and hydrometallurgical plant.

The objective of the consultancy requested from MiningiDEAS was to support the operational management of the Mine Manager. The following stages were defined:

- Data analysis using information from the Dispatch system: A study of historical productions was conducted, and gaps between past production trends and current ones were identified.

- Determination of variables to be controlled in each mining group: Once the most important KPIs were established, methods for reliable and stable monitoring were defined.

- Establishment of Performance Dialogues: With the aim of informing supervisors about production trends and engaging them in improving field conditions, they were invited to a weekly management analysis meeting. During these meetings, all improving indicators were highlighted, production goals were reminded, and operational practices were standardized.

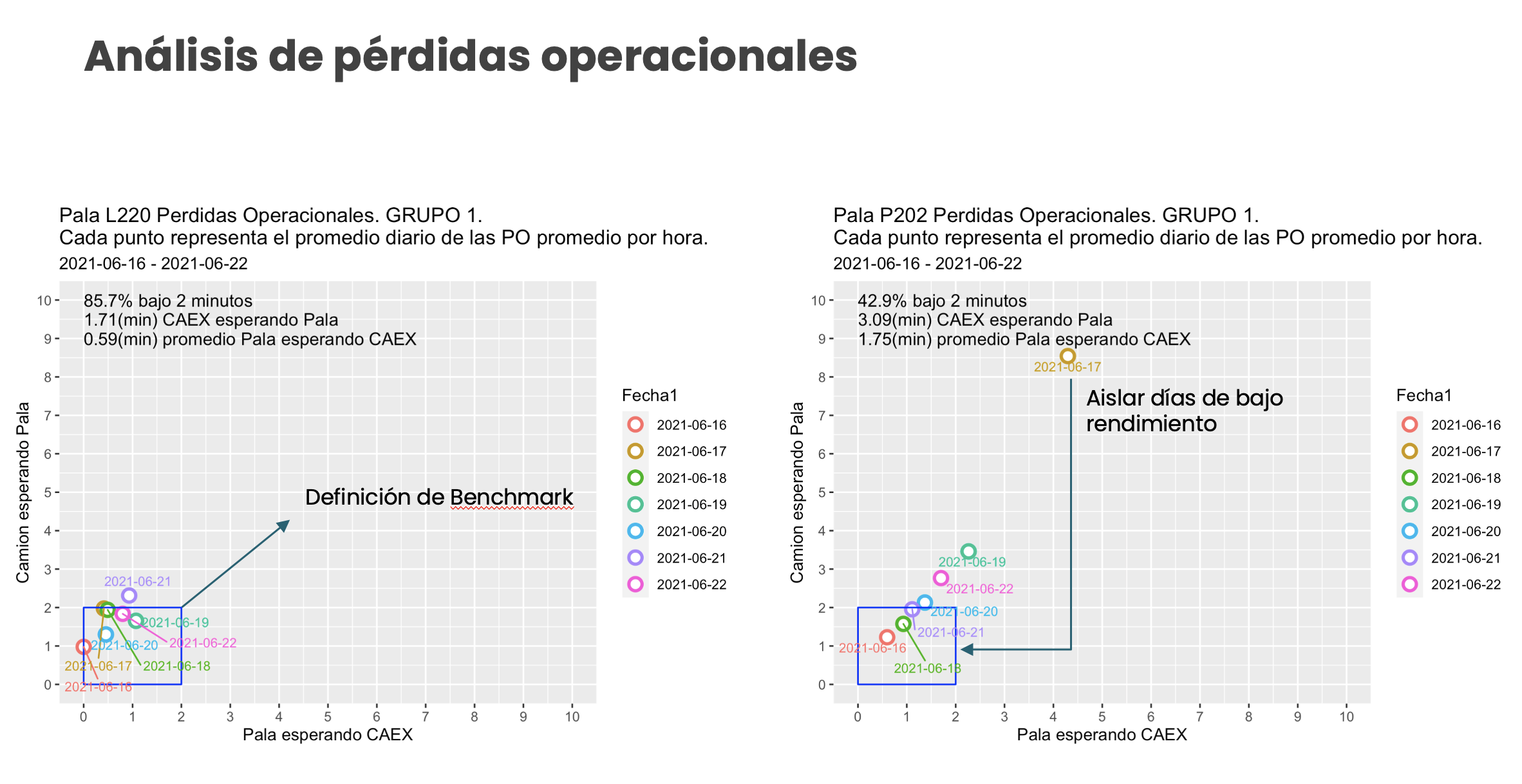

The primary objective was to increase the level of ore production sent to the plant, which required increasing the effective hours of mining equipment fleets. MiningiDEAS implemented the following monitoring panel to reduce operational losses of shovels and trucks.

Operational losses refer to the time a shovel loses between one loading and another due to not having a truck to load. There are also productivity losses when a shovel is assigned more trucks than it can load, resulting in queues of trucks waiting to be loaded.

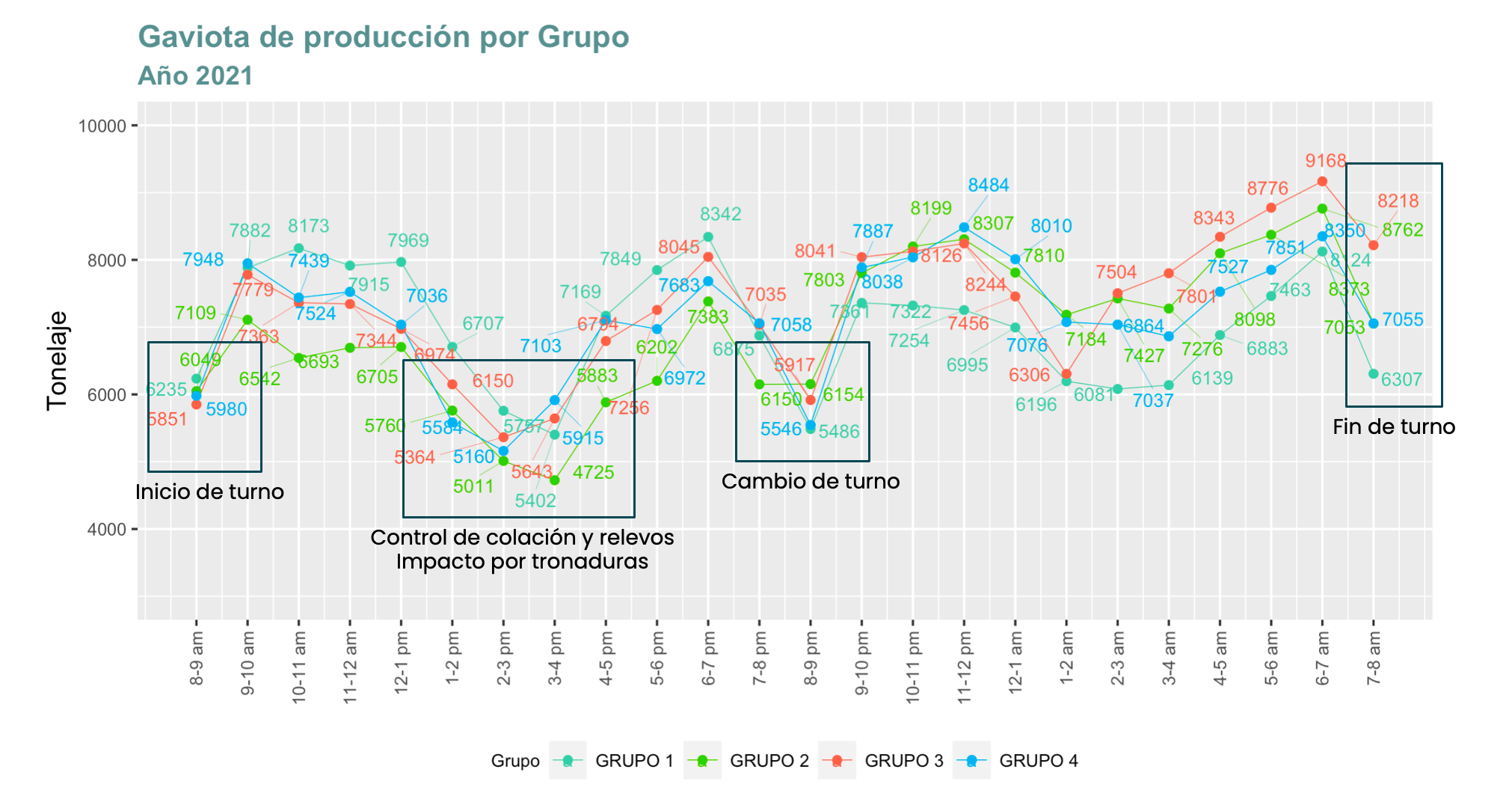

As shift supervisors and operations managers became aware of production measures, they improved each hour of the shift, especially at the beginning, lunchtime, and end of the shift.

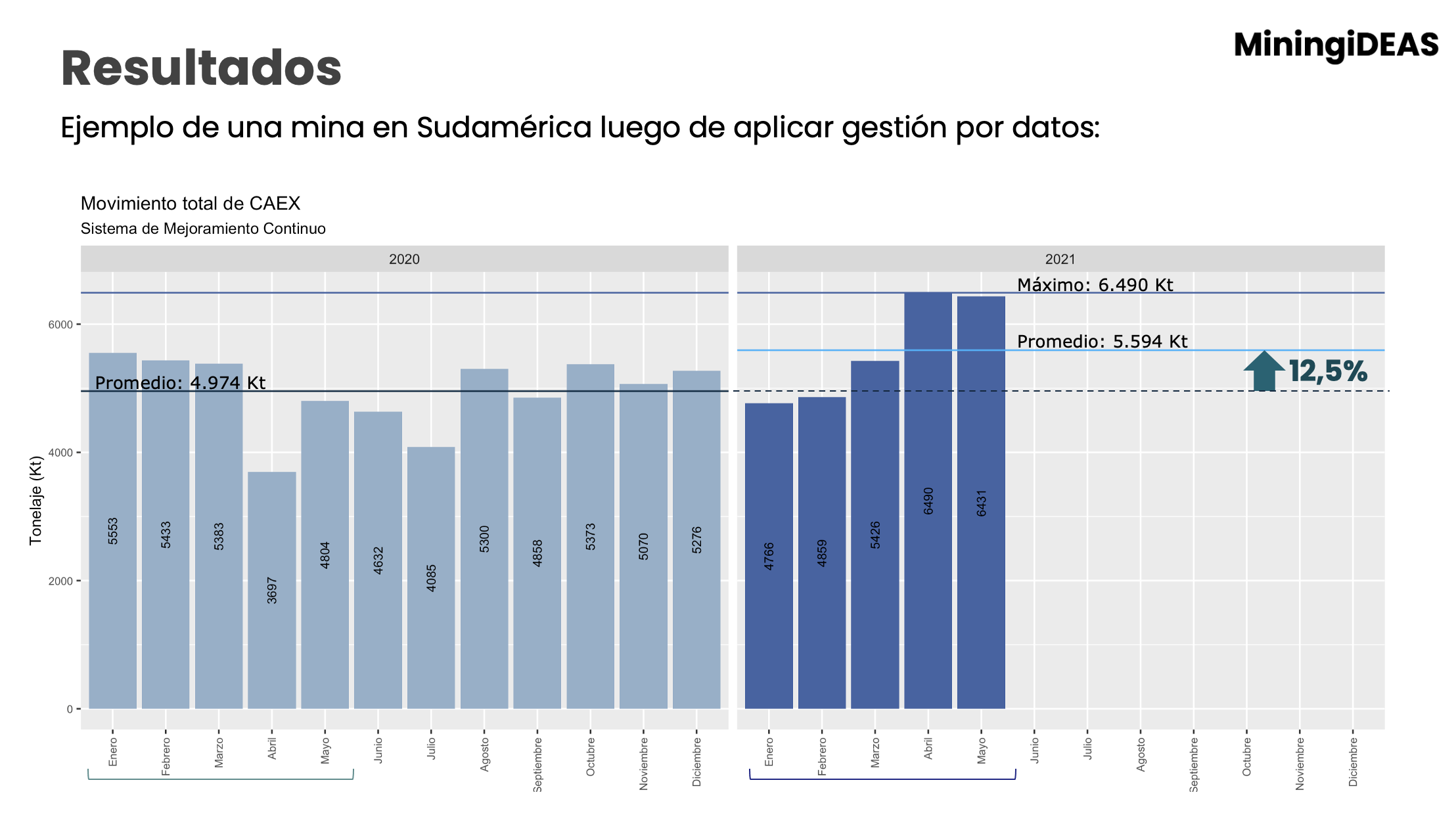

As a result of this and other analyses, which included reducing delay times, reserve times, maintenance times, etc., the overall mine production increased by approximately 12.5% compared to the previous year. These data can be seen in the following graph:

Enlaces de interés

Check out part 1 of our mining podcast where we discuss these topics.